Results

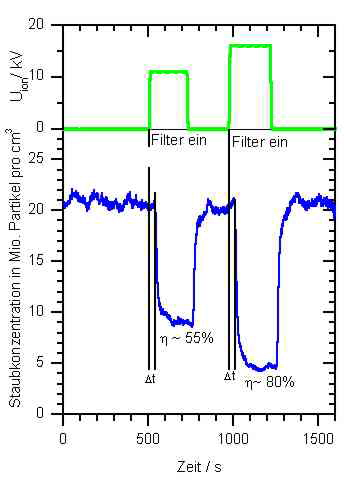

This figure shows the effect when switching the Miniature Partcle Absorber on and off. Already an operating voltage of 11 kV can reduce the particle concentration in the flue gas by 50%. At a typical operating voltage of 16kV the reduction is about 80%. Choosing voltage and geometry in suitable manner an even higher seperation efficiency is achievable.

From this figure it is obvious that the separation is starting immediately after switching on the MiniPab. The time delay Dt shown in the figure is due to the transport velocity of the flue gas withing flue pipe and sampling line.

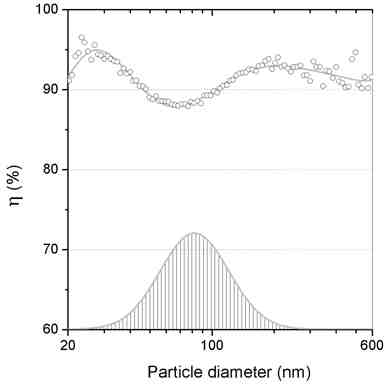

The figure on the right demonstrates the effect of particle size on the separation efficiency.

Most of the particles in the flue gas of wood fired appliances have diameters between 50 bis 200nm. The lower plot shows a typical size distribution of the particles in the flue gas of wood fired furnaces.

MiniPab: Miniature Particle Absorber for small wood fired furnaces

updated

21. July 2006